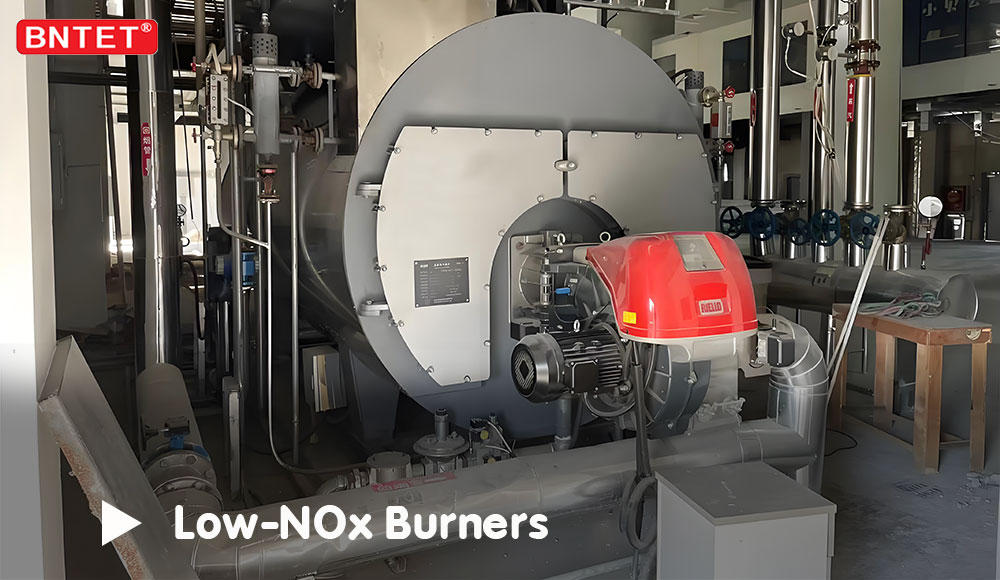

Working Principle of Low-NOx Burners

2025-06-09 16:41:09

The core objective of a Low-NOx Burner (LNB) is to reduce the formation of nitrogen oxides (NOx) during combustion, primarily by optimizing combustion conditions to suppress NOx generation. Its technical principles can be categorized as follows:

1. Reducing Combustion Temperature (Thermal NOx Control)

One of the main sources of NOx is thermal NOx, which occurs when nitrogen (N₂) and oxygen (O₂) in the air react at high temperatures (typically above 1400°C).

Technical Methods:

Staged Combustion:

Air Staging: Introduce a limited amount of air initially (fuel-rich combustion) to lower flame temperature, then supply the remaining air to complete combustion.

Fuel Staging: Burn part of the fuel first, then combust the remaining fuel in a low-temperature zone to avoid localized high temperatures.

Flue Gas Recirculation (FGR):

Recirculate a portion of cooled flue gas into the combustion air to dilute oxygen concentration and absorb heat, lowering combustion temperature.

2. Shortening Residence Time in High-Temperature Zones (Rapid Cooling)

Optimize burner design (e.g., swirl flow) to create a shorter, wider flame, reducing high-temperature duration and thus NOx formation.

3. Chemical Suppression (Reducing Fuel NOx)

If the fuel contains nitrogen (e.g., biomass, coal), fuel NOx is generated during combustion.

Technical Methods:

Lean Combustion: Maintain an oxygen-deficient environment to promote nitrogen conversion into N₂ rather than NOx.

Reduction Zone Control: Create a reducing atmosphere (e.g., with CO or CH₄) in the early combustion stage to convert nitrogen into N₂ instead of NO.

Comparison of Typical Low-NOx Combustion Technologies

| Technology | Principle | NOx Reduction Efficiency | Applications |

|---|---|---|---|

| Air Staged Combustion | Phased oxygen supply to lower peak temperature | 30%~50% | Gas/oil boilers |

| Flue Gas Recirculation (FGR) | Mixing flue gas to reduce O₂ concentration and temperature | 40%~70% | Gas turbines, industrial furnaces |

| Lean Premixed Combustion | Pre-mixing fuel and air for uniform combustion | 50%~80% | Gas boilers |

| Selective Non-Catalytic Reduction (SNCR) | Injecting ammonia/urea to reduce NOx at high temperatures | 30%~60% | Coal-fired boilers |

Application Examples

Gas Boilers: Use FGR + staged combustion to reduce NOx emissions to <30 mg/m³.

Biomass Burners: Combine air staging + reduction zone control to minimize fuel NOx.

Cement Kilns: Employ low-NOx burners + SNCR to achieve ultra-low emissions.

Conclusion

The core principle of low-NOx burners is to control temperature, regulate oxygen levels, and optimize chemical reactions to suppress NOx formation, making them a key technology for industrial emission reduction.