What is RTO regenerative incinerator burner

2025-06-11 10:10:33

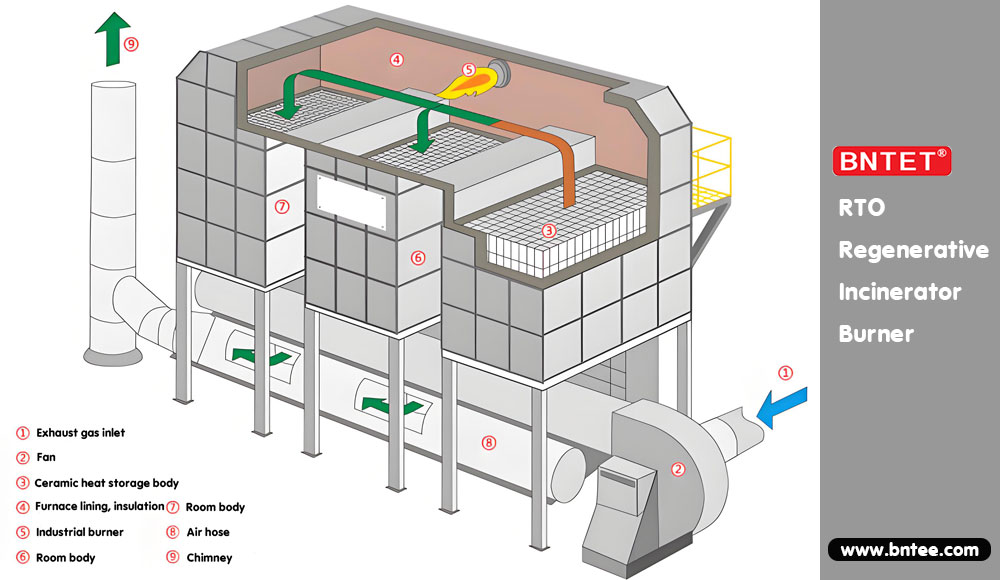

The RTO (Regenerative Thermal Oxidizer) burner is a core component of VOC (Volatile Organic Compounds) waste gas treatment systems. It utilizes regenerative ceramic beds to recover heat, enabling highly efficient combustion (destruction efficiency ≥99%) with ultra-low energy consumption. Its key feature is the alternating cycle of combustion and heat regeneration, where exhaust gases are heated to 800–1000°C to decompose VOCs into CO₂ and H₂O.

I. Working Principle of RTO Burners

Heat Regeneration-Combustion Cycle

Combustion Phase:

Exhaust gas passes through Ceramic Bed A, preheating to near combustion temperature (700–900°C).

The burner supplements heat, raising the gas temperature to 800–1000°C for complete VOC destruction.

High-temperature flue gas transfers heat to Ceramic Bed B before being discharged at low temperature (<150°C).

Switching Phase (every 1–3 minutes):

Gas flow reverses: Bed B preheats incoming gas while Bed A stores heat, with the burner adjusting flame intensity.

Energy-Saving Core

The ceramic beds recover >95% of waste heat, reducing energy consumption by 50–70% compared to direct combustion.

II. Core Components of RTO Burners

| Component | Function | Technical Requirements |

|---|---|---|

| Burner Unit | Provides high-temperature flames to assist VOC combustion. | High-temperature resistance (≥1200°C), low-NOx design. |

| Ceramic Heat Beds | Store and release heat (honeycomb or pelletized ceramics). | Thermal shock resistance, high surface area (≥500 m²/m³). |

| Valve System | Controls gas flow direction (four-way or butterfly valves). | Fast response (<1 sec), high sealing performance. |

| Control System | Manages temperature, switching sequence, and safety interlocks. | PLC + O₂ sensors, supports auto/manual modes. |

III. Technical Features of RTO Burners

Ultra-Low Energy Consumption

Requires minimal supplemental fuel (e.g., natural gas), ideal for low-concentration VOCs (100–2000 ppm).

High Destruction Efficiency

Combustion temperature ≥800°C, VOC destruction rate ≥99%, compliant with EPA/EU standards.

Low NOx Emissions

Utilizes staged combustion or Flue Gas Recirculation (FGR), keeping NOx below <50 mg/m³.

Adaptability to Complex Gases

Handles corrosive components (e.g., sulfur, halogens) with materials like 310S stainless steel.

IV. RTO Burner vs. Other Incineration Technologies

| Parameter | RTO Burner | Thermal Oxidizer (TO) | Catalytic Oxidizer (CO) |

|---|---|---|---|

| Operating Temp. | 800–1000°C | 800–1200°C | 300–500°C (with catalyst) |

| Energy Use | Very low (heat recovery >95%) | High (continuous burning) | Moderate |

| VOC Concentration | 100–2000 ppm | >5000 ppm | <500 ppm |

| NOx Generation | Low (FGR technology) | High | Lowest |

V. Key Selection Criteria

Exhaust Gas Flow Rate: Determines RTO size (e.g., 10,000 Nm³/h requires matching burner capacity).

VOC Composition: Corrosive gases (e.g., chlorine/sulfur) demand anti-corrosion design.

Emission Standards: Strict regions may require additional SCR systems for NOx control.

Brand Selection:

International: Durr, Eisenmann, Anguil ,BNTET(high-precision control).

VI. FAQs

Q: Why are RTO burners more fuel-efficient than TO?

A: Ceramic beds recover waste heat to preheat incoming gas, minimizing supplemental fuel needs.

Q: Do RTO burners require frequent maintenance?

A: Ceramic beds need annual inspection for dust buildup; burner nozzles require replacement every 2 years; valves need regular lubrication.

Q: Can RTOs handle high VOC concentrations?

A: Yes, but requires LEL monitoring to prevent explosions (typically designed for ≤25% LEL).

Conclusion

RTO regenerative burners, with their heat recovery + intermittent combustion, are among the most energy-efficient VOC treatment technologies, especially for continuous, low-to-medium concentration emissions. Selection must consider exhaust characteristics, flow rate, and regulations, prioritizing suppliers with proven case studies.