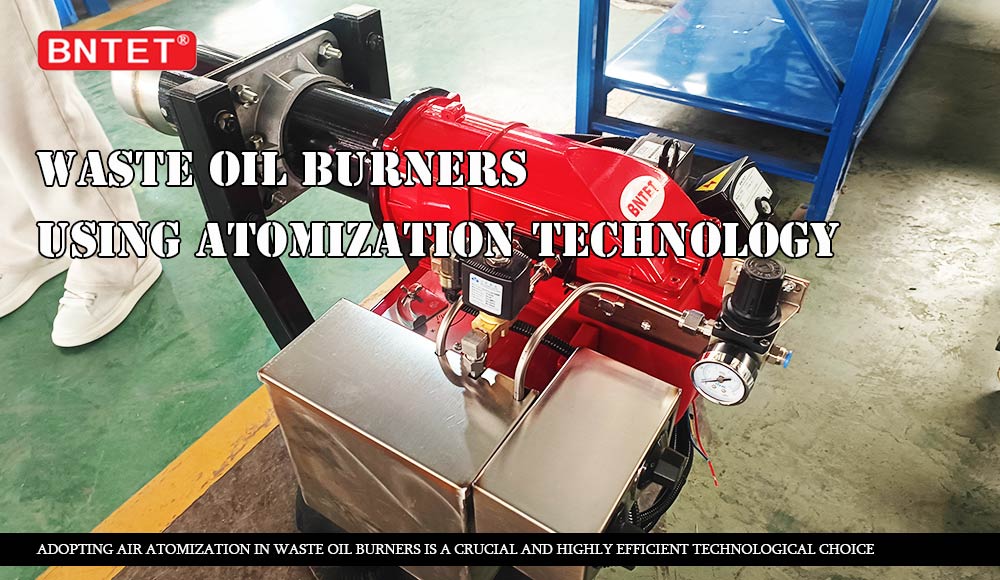

Benefits of using air atomization for waste oil burners

2025-09-28 17:09:05

Adopting air atomization in waste oil burners is a crucial and highly efficient technological choice. Its benefits are primarily reflected in combustion efficiency, equipment reliability, fuel adaptability, and environmental performance, among other aspects.

The following outlines the main advantages of air atomization technology, with a comparison to mechanical pressure atomization for better understanding:

1. Superior Atomization and Combustion Efficiency

Principle: Air atomization utilizes a high-speed airflow (typically provided by compressed air or a blower) to impact and tear apart the high-viscosity waste oil, forming extremely fine and uniform oil droplets.

Benefits:

Finer Droplets: The surface area of the oil droplets is greatly increased, allowing for more thorough mixing with air.

More Complete Combustion: Near-perfect fuel-air mixing ensures the waste oil is completely burned within the combustion chamber, maximizing heat extraction.

High Thermal Efficiency: Reduces heat loss due to incomplete combustion, directly improving the burner's overall thermal efficiency.

2. Strong Adaptability to High-Viscosity, Low-Quality Fuels

Principle: Waste oils (such as waste engine oil, vegetable oil, animal fat, etc.) are typically highly viscous and contain impurities. Mechanical atomization nozzles are prone to clogging or cannot effectively atomize high-viscosity liquids.

Benefits:

Handles High-Viscosity Oils: The kinetic energy of the air can effectively overcome the oil's viscosity, enabling good atomization even for cold or less precisely pre-treated waste oil.

Strong Resistance to Impurities: The oil passages in air atomization nozzles are generally larger than those in mechanical nozzles, making them less susceptible to clogging from small particles in the oil, thereby reducing maintenance frequency.

3. Wider Turndown Ratio

Principle: By adjusting the flow rates of both air and oil, the combustion power (load) can be easily varied over a wide range while maintaining stable atomization quality.

Benefits:

Flexible Operation: The burner can smoothly operate from low to high load based on thermal demand (e.g., boiler steam pressure), with a turndown ratio potentially reaching 1:5 or higher. This is crucial for applications with fluctuating heat demands.

Comparison: With mechanical pressure atomization, reduced oil pressure at low loads leads to a sharp decline in atomization quality, producing significant black smoke.

4. Lower Ignition Difficulty and More Stable Flame

Principle: Fine atomization makes the oil droplets easier to ignite. Good fuel-air mixing also ensures flame stability and controllable shape.

Benefits:

High Ignition Success Rate: Reduces the risk of ignition failure and combustion puffbacks.

Stable Flame: Prevents flame flicker, extinction, or lifting from the burner head, ensuring continuous and safe equipment operation.

5. Excellent Environmental Performance (Low Emissions)

Principle: Complete combustion is the foundation of low emissions.

Benefits:

Significantly Reduces Black Smoke (Soot): Almost eliminates heavy black smoke caused by incomplete combustion.

Lowers Carbon Monoxide (CO): Complete combustion minimizes CO generation.

Reduces Unburned Hydrocarbons (UHC): Prevents the direct emission of unburned waste oil.

Helps Control Pollutants: Stable flame and combustion conditions also create a favorable basis for subsequent control of pollutants like Nitrogen Oxides (NOx).

6. Improved Equipment Reliability and Reduced Maintenance Costs

Principle: The nozzles are less prone to clogging, and requirements for fuel pre-treatment (filtration, heating) are relatively less stringent.

Benefits:

Reduces Downtime: Extends the cleaning and replacement cycles for nozzles.

Lowers Pre-treatment Costs: The required fuel heating temperature may be lower than for mechanical atomization, saving energy. The filtration system also doesn't need to be as fine.

Simple Comparison with Mechanical Pressure Atomization

| Feature | Air Atomization | Mechanical Pressure Atomization |

|---|---|---|

| Atomization Principle | Kinetic energy of high-speed air | Shear force from high-pressure oil passing through a small orifice |

| Sensitivity to Viscosity | Low, good adaptability | High, requires precise control of oil temperature and viscosity |

| Droplet Size | Finer and more uniform | Relatively coarser, greatly affected by oil pressure |

| Turndown Ratio | Wide (e.g., 1:5) | Narrow (e.g., 1:2) |

| Clogging Resistance | Strong | Weak |

| System Complexity | Requires an air source (compressor or blower) | Requires a high-pressure oil pump |

| Suitable Fuels | Ideal for inferior, high-viscosity waste oils | More suitable for clean, low-viscosity standard fuel oils |

Summary

For waste oil burners, which are specifically designed to handle high-viscosity, complex, and impurity-containing fuels, air atomization is almost a mandatory choice. By accepting a slight increase in system complexity (adding an air source), it delivers extremely high combustion efficiency, excellent fuel adaptability, stable operating conditions, superior environmental performance, and lower maintenance requirements. This ensures that the entire waste oil treatment or energy recovery process can operate economically, reliably, and in an environmentally friendly manner.