Detailed Explanation of FGR Nitrogen Reduction Technology

2025-06-10 16:26:26

1. Technical Definition

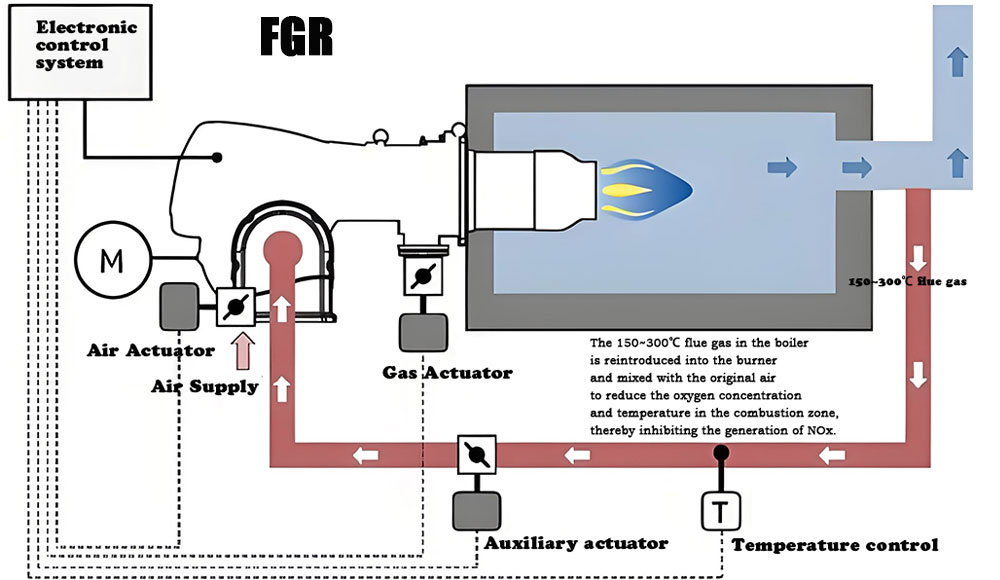

FGR (Flue Gas Recirculation) is a low-NOx combustion technology that reduces nitrogen oxide emissions by recirculating a portion of flue gas from the boiler/burner exhaust back into the combustion air. This lowers the oxygen concentration and temperature in the combustion zone, thereby inhibiting NOx formation. The core principles are:

Physical Cooling: Low-temperature flue gas (typically 150–300°C) dilutes the combustion air and absorbs heat from the flame.

Chemical Suppression: Reduced oxygen partial pressure disrupts the high-temperature, oxygen-rich environment required for NOx formation.

2. Working Principle

Flue Gas Extraction: 10%–30% of low-temperature flue gas is extracted from the boiler exhaust (after the dust collector).

Mixing Regulation: The flue gas is mixed with combustion air via dedicated ducts (reducing oxygen concentration to 15%–18%).

Combustion Control: Low-oxygen combustion slows reaction rates, homogenizes flame temperature, and reduces peak temperatures by 100–200°C.

NOx Reduction Mechanism:

Thermal NOx: Every 100°C drop in temperature reduces NOx generation by ~35%.

Fuel NOx: Oxygen-deficient conditions suppress the conversion of nitrogen in fuel to NOx.

3. Key Technical Parameters

| Parameter | Typical Range | Impact |

|---|---|---|

| Flue Gas Recirculation Ratio | 10%–30% | >30% may cause combustion instability |

| Post-Mixing O₂ Concentration | 15%–18% | <15% risks incomplete combustion |

| Flue Gas Temperature | 150–300°C | Too high reduces cooling effect; too low increases corrosion risk |

| System Resistance | 500–1000Pa | Requires high-pressure fans to overcome resistance |

4. System Components

Flue Gas Extraction: Corrosion-resistant induced draft fan, control valve.

Mixing Device: Static/dynamic mixer for uniform flue gas-air blending.

Safety Controls:

CO/O₂ real-time monitoring to prevent oxygen-deficient combustion.

Emergency shutoff valve to avoid flue gas backflow.

5. Application Performance

Emission Reduction: Lowers NOx by 40%–70% (e.g., gas boiler NOx reduced from 100 mg/m³ to <30 mg/m³).

Applicable Scenarios:

Gas boilers, gas turbines (must prevent condensation corrosion).

Oil-fired boilers (requires soot deposition control).

Case Study:

A petrochemical plant’s gas boiler achieved NOx reduction from 80 mg/m³ to 25 mg/m³ using FGR, with only a 1.5% increase in fuel consumption.

6. Advantages and Limitations

Advantages:

Low retrofit cost (~1/3 to 1/2 of SCR systems).

No chemical reagents required; simple operation and maintenance.

Limitations:

Limited effect on high-nitrogen fuels (e.g., coal, biomass).

May reduce boiler efficiency by 1%–3% (due to increased fan power consumption).

7. Synergy with Other Technologies

FGR + Staged Combustion: FGR reduces baseline NOx, while staged combustion further cuts emissions.

FGR + SCR: FGR serves as a pre-treatment to reduce urea consumption in SCR systems.

Conclusion

FGR achieves efficient NOx reduction through "flue gas dilution + low-temperature combustion", making it a preferred solution for gas-fired boiler retrofits. However, the recirculation ratio must be carefully designed based on fuel type, emission requirements, and system compatibility.