High-Speed Burners vs Standard Burners

2025-07-30 15:03:55

The primary distinctions between high-speed burners and conventional burners lie in combustion methods, gas flow velocity, application scenarios, and performance characteristics. Below is a detailed comparison:

1. Gas Flow Velocity

High-Speed Burner:

High exit gas velocity (typically 100–300 m/s or higher).

Utilizes specialized designs (e.g., pressurized combustion chambers or Venturi structures) to accelerate high-temperature gas, creating intense convection and agitation.

Conventional Burner:

Lower exit gas velocity (generally <50 m/s).

Relies on natural diffusion or low-speed jet combustion, resulting in slower mixing and heat transfer.

2. Combustion Efficiency & Temperature Uniformity

High-Speed Burner:

Efficient mixing: High-velocity flow ensures thorough fuel-air mixing, enabling complete combustion and higher efficiency.

Uniform temperature: High-speed jets enhance gas circulation, minimizing localized hot/cold spots (ideal for applications like heat treatment furnaces).

Conventional Burner:

Mixing depends on diffusion or low-speed turbulence, often leading to incomplete combustion or uneven temperature distribution.

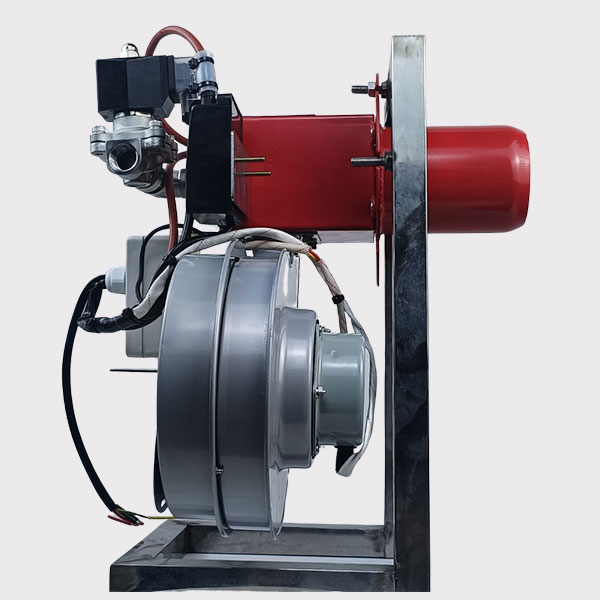

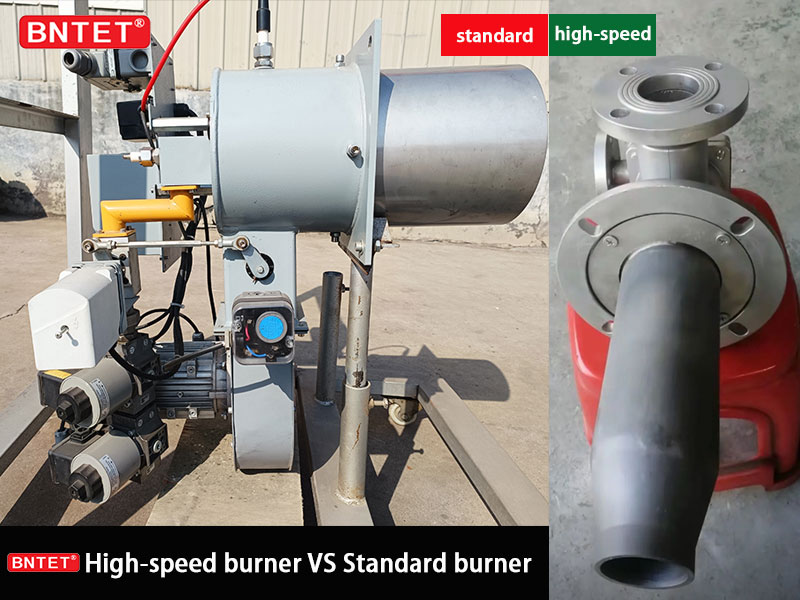

3. Structural Design

High-Speed Burner:

Equipped with an integrated combustion chamber where fuel is fully burned before being accelerated through a narrowed nozzle.

May require high-temperature-resistant materials (e.g., ceramics) to withstand extreme conditions.

Conventional Burner:

Simple design, typically diffusion or premixed type, without high-velocity jet mechanisms.

4. Application Scenarios

High-Speed Burner:

Suitable for rapid heating, high temperature uniformity, or forced convection, such as:

Heat treatment furnaces, continuous casting/rolling lines

Glass melting furnaces, petrochemical cracking furnaces

Industrial kilns requiring fast heating

Conventional Burner:

Used in low-velocity applications: small boilers, household stoves, traditional industrial furnaces, etc.

5. Energy Consumption & Pollution Control

High-Speed Burner:

More complete combustion reduces pollutants like NOx (though excessive flame temperatures may increase NOx).

Generally lower energy consumption (due to higher thermal efficiency).

Conventional Burner:

Prone to incomplete combustion at low loads, potentially emitting CO and unburned hydrocarbons.

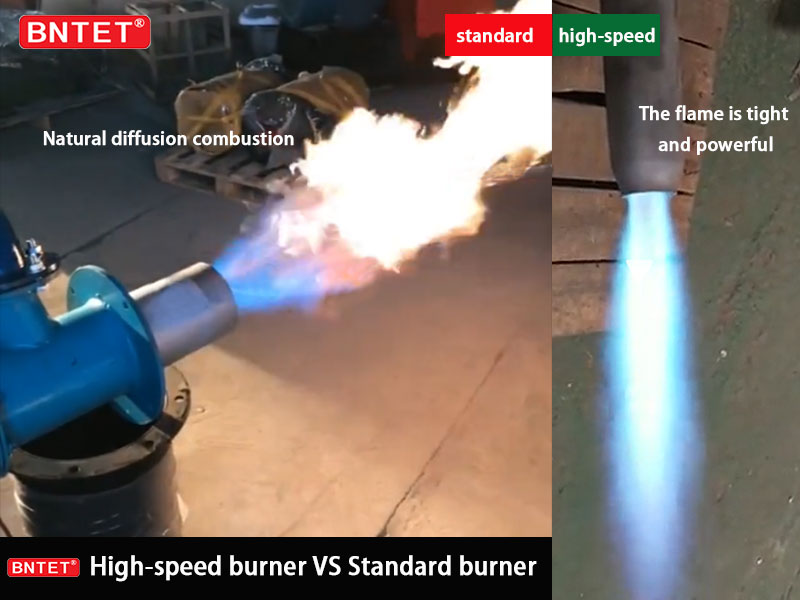

6. Flame Characteristics

High-Speed Burner:

Short, wide flame with high-impact jets, suitable for direct workpiece heating.

Conventional Burner:

Longer, softer flame with diffusion combustion.

Summary Table

| Feature | High-Speed Burner | Conventional Burner |

|---|---|---|

| Flow Velocity | 100–300+ m/s | Typically <50 m/s |

| Combustion Efficiency | High (thorough mixing) | Lower (diffusion-dependent) |

| Temperature Uniformity | Excellent (forced convection) | Moderate |

| Structural Complexity | High (combustion chamber, advanced materials) | Simple |

| Typical Applications | Heat treatment, glass kilns, rapid heating | Boilers, household stoves, traditional kilns |

| Pollutant Emissions | Lower (but NOx control needed at high temps) | Potentially higher (incomplete combustion) |

Selection Guidelines

Prioritize high-speed burners for rapid heating, uniform temperatures, or intense convection.

Opt for conventional burners for cost-sensitive or simple applications.

High-speed burners excel in high-temperature industrial settings but entail higher design/maintenance costs. Choose based on actual requirements.

This translation maintains technical accuracy while ensuring clarity for an international engineering audience. Let me know if you'd like any refinements!