How to Deal with Ring Formation (Buildup) in Rotary Kilns

2025-06-26 11:28:26

Ring formation (also called "buildup" or "clinker rings") is a common issue in rotary kilns that affects production efficiency and equipment safety. The treatment approach depends on the cause, location, and severity of the buildup. Below is a systematic guide to handling and preventing kiln rings.

I. Causes of Ring Formation

Raw Material Factors

Low-melting-point materials (e.g., high-alkali, high-sulfur feed) or excessive fine particles can fuse and adhere to the kiln wall.

Operational Issues

Overheating in the burning zone or uneven feed distribution leads to localized sintering.

Equipment Problems

Low kiln rotation speed, cyclone blockage, or burner flame deflection increase material buildup.

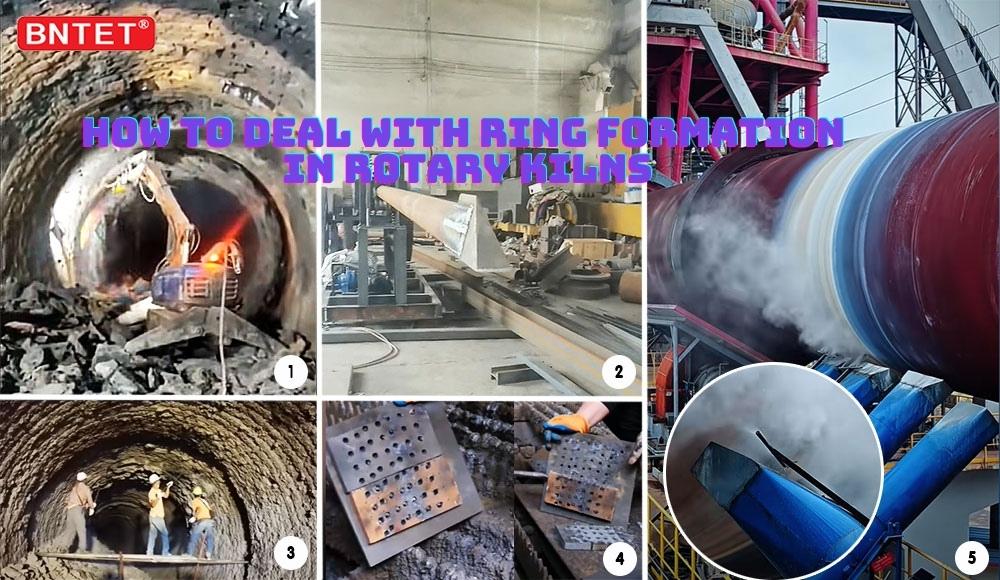

II. Methods for Removing Rings

(1) Mechanical Cleaning

Manual Removal(image 3)

Tools: Steel rods, pneumatic hammers, high-pressure water jets.

Application: Used during shutdowns for kiln mouth or shallow buildup.

Disadvantages: Low efficiency, high-risk operation.

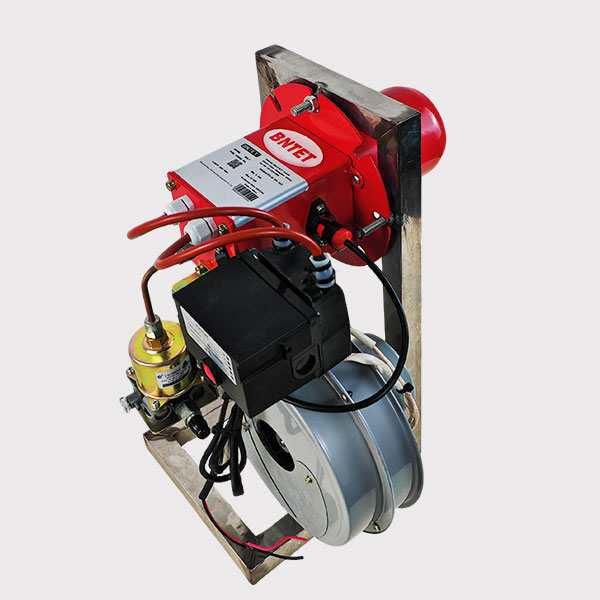

Mechanical Ring Breakers

Poking Machines: Designed for kiln mouth rings (hydraulic reciprocating rods, online operation).(image 2)

Rotary Cutters/Blades: Installed in the kiln’s mid-section to remove buildup in the burning zone (requires synchronized kiln rotation).

Robotic Cleaners: Use vision systems to detect and precisely remove rings (e.g., in cement kilns).(image 1)

(2) Thermal Adjustment

Controlled Cooling(image 5)

Temporarily reduce burning zone temperature by 50–100°C to induce thermal cracking of rings.

Caution: Avoid rapid cooling to prevent refractory damage.

Flame Shape Optimization

Shorten flame length to prevent localized overheating.

(3) Chemical Assistance

Anti-Ring Agents

Inject fluorine/chlorine-based compounds (e.g., CaF₂) from the kiln inlet to lower the melting point of buildup (use cautiously to avoid corrosion).

(4) Blasting (Last Resort)

Controlled Explosives: Used for extremely hard rings (requires professional handling).

III. Key Preventive Measures

Raw Material Control

Pre-homogenize feed to reduce harmful components (K₂O, Na₂O, SO₃).

Adjust raw meal fineness (avoid excessive fines) and increase SiO₂/Al₂O₃ ratio.

Operational Optimization

Stabilize feed rate to prevent temperature fluctuations.

Maintain proper kiln speed (typically 2–4 rpm) to minimize material retention time.

Equipment Maintenance

Regularly inspect rotary kiln burners and cyclones to prevent blockages or flame deflection.

Monitor kiln coating with infrared thermography for abnormal wall temperatures.

Refractory Selection(image 4)

Use anti-coating bricks (e.g., magnesia-alumina spinel) in the burning zone.

IV. Treatment Focus by Kiln Type

| Kiln Type | Ring Characteristics | Recommended Solutions |

|---|---|---|

| Cement Kiln | Sulfate/alkali rings in burning zone | Mechanical cleaners + flame adjustment + low-alkali feed |

| Metallurgical Kiln | Hard silicate rings | Hydraulic impact breakers + post-calcination cleaning |

| Lime Kiln | Low-temperature buildup at kiln exit | Poking machines + increased rotation speed |

| Chemical Kiln | Organic deposits | Chemical cleaning + nitrogen-protected combustion |

V. Example Workflow (Cement Kiln)

Online Monitoring: Infrared detection of ring location/thickness.

Initial Adjustment: Reduce coal feed, optimize flame shape.

Mechanical Intervention: Activate mid-kiln ring breaker for burning zone; use poking machine at kiln mouth.

Shutdown Maintenance (if unresolved): Manual blasting + refractory inspection.

VI. Key Notes

Safety First: High-temperature operations require protective gear; no solo work permitted.

Avoid Over-Cleaning: Excessive removal accelerates refractory wear.

Data Analysis: Track ring frequency/location to optimize process parameters.

By adopting a "prevention-first, cleaning-supplement" strategy, ring-related production losses can be minimized. If rings recur frequently, conduct a deep analysis of raw materials or process flaws.