What is the function of the oil filter installed on the waste oil burner

2025-05-24 09:58:32

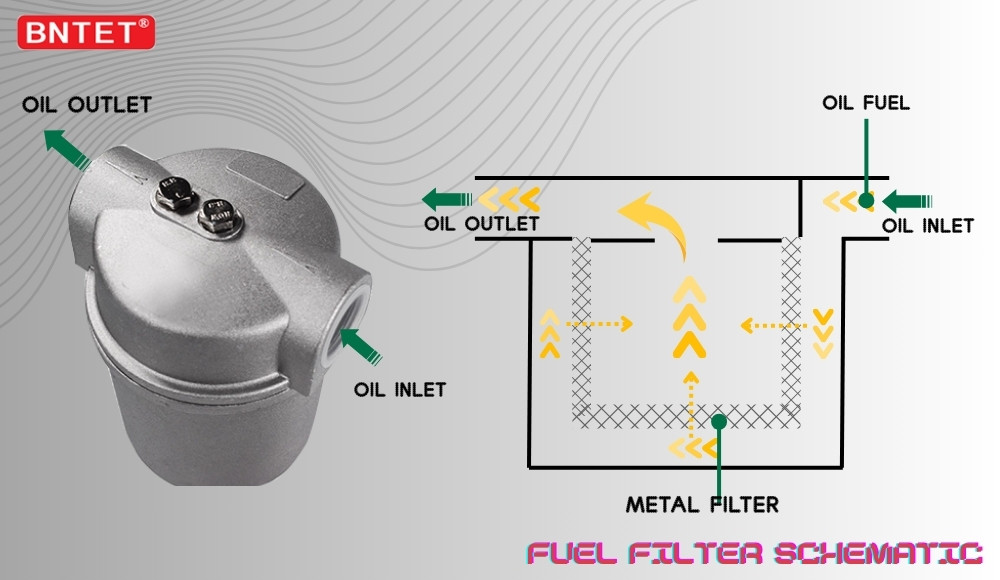

The primary function of the oil filter installed in a waste oil burner is to purify the fuel (waste oil), ensuring stable and efficient operation of the burner while extending the equipment's service life. Specific functions are as follows:

1. Core Functions

Filter Solid Impurities

Removes metal debris, carbon particles, food residues, etc. (common in cooking waste oil) to prevent clogging of the fuel nozzle or wear on the oil pump.Separate Water

Uses oil filter media adsorption or centrifugal force to remove free water from waste oil, avoiding combustion instability caused by water vaporization (which may lead to explosive combustion).Intercept Viscous Residues

Filters sticky residues formed by high-temperature oxidation, preventing coking in the combustion chamber.

2. Key Protected Components

| Component | Risks Without a Oil Filter |

|---|---|

| Oil Pump | Metal debris jams the rotor, causing low pressure |

| Nozzle | Clogging (0.1mm-level precision), poor atomization |

| Solenoid Valve | Residue adhesion leading to valve sticking |

| Combustion Chamber | Increased carbon buildup, thermal efficiency ↓30%+ |

3. Oil filter Types & Selection Guide

(1) Primary Oil Filter (Pre-Filtration)

Mesh Size: 100-150μm (stainless steel mesh)

Location: Oil tank outlet

Application: Waste oil with large particles (e.g., gutter oil)

(2) Fine Oil Filter (Main Filtration)

Oil Filter Media: Glass fiber/ceramic

Filtration Precision: 10-25μm

Location: Before the oil pump

Mandatory Use: For biodiesel or finely recycled oil

(3) Magnetic Oil Filter (Optional)

Uses strong magnets to adsorb iron particles, suitable for waste oil containing metal wear debris.

4. Maintenance Guidelines

Replacement Cycle:

Light waste oil (e.g., vegetable oil): Every 500 operating hours

Heavy waste oil (e.g., engine oil): Every 200 operating hours

Immediate replacement required if pressure drop alarm exceeds 0.3MPa

Cleaning Methods:

Metal mesh: Ultrasonic cleaning with diesel (28kHz frequency)

Paper filter elements: Non-reusable

5. Symptoms of Oil Filter Failure

Ignition delay >5 seconds

Flame turns red (normal: bright blue)

Increased oil pump noise (caused by insufficient flow due to clogging)

Recommendation:

Install a transparent inspection window after the oil filter for regular oil cleanliness checks.

For high-viscosity waste oil (e.g., animal fat), preheat to 60-80°C before filtration.