What is Nozzle-Mix Burners

2025-02-06 11:39:48

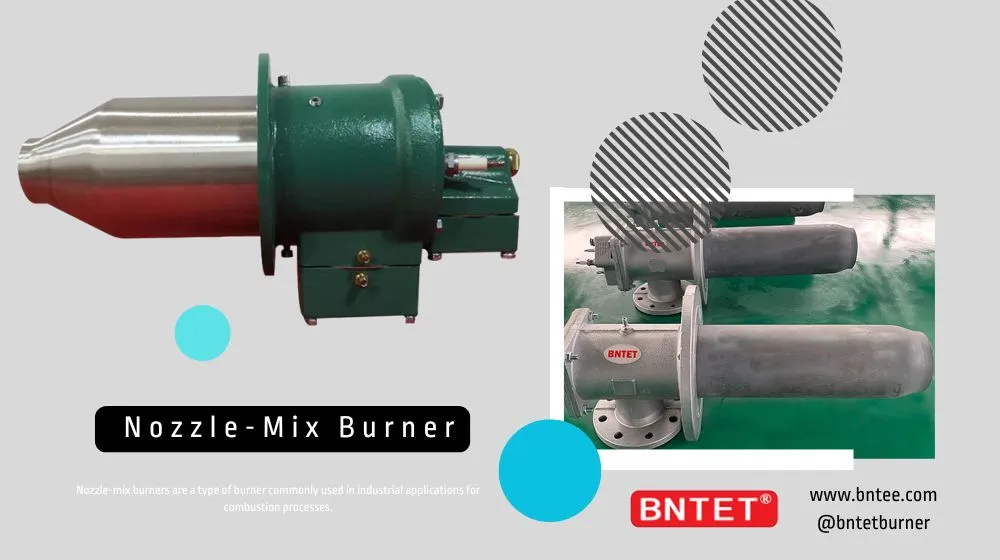

Nozzle-mix burners are a type of burner commonly used in industrial applications for combustion processes. They are designed to mix fuel and air before combustion occurs, providing efficient and stable flame characteristics. Here’s a breakdown of their key features and functionalities:

Key Features of Nozzle-Mix Burners

Design:

Nozzle: The burner has a nozzle that atomizes the fuel, breaking it into fine droplets. This enhances the mixing of fuel and air.

Mixing Chamber: The nozzle directs the atomized fuel into a mixing chamber where it combines with air before entering the combustion zone.

Fuel Types:

Nozzle-mix burners can typically handle various types of fuels, including natural gas, propane, and oil.

Air Supply:

They can operate with either forced air (using fans) or natural draft, depending on the design and application.

Flame Stability:

The design allows for stable flames, which is crucial for many industrial processes. The pre-mixing of fuel and air helps to achieve a uniform combustion process.

Applications:

Commonly used in industrial furnaces, boilers, and other heating applications where precise control of combustion is required.

Advantages

Efficiency: The pre-mixing of fuel and air leads to more complete combustion, improving thermal efficiency and reducing emissions.

Flexibility: Can be adapted for different fuels and operational conditions.

Control: Provides better control over the combustion process, allowing for adjustments to optimize performance.

Disadvantages

Complexity: The design can be more complex compared to other burner types, potentially leading to higher maintenance needs.

Cost: Initial setup and equipment costs can be higher than simpler burner designs.

Conclusion

Nozzle-mix burners are effective for applications requiring efficient and stable combustion. Their ability to mix fuel and air effectively makes them suitable for a variety of industrial processes, contributing to improved efficiency and lower emissions.