Industrial Gas Burner BNG6

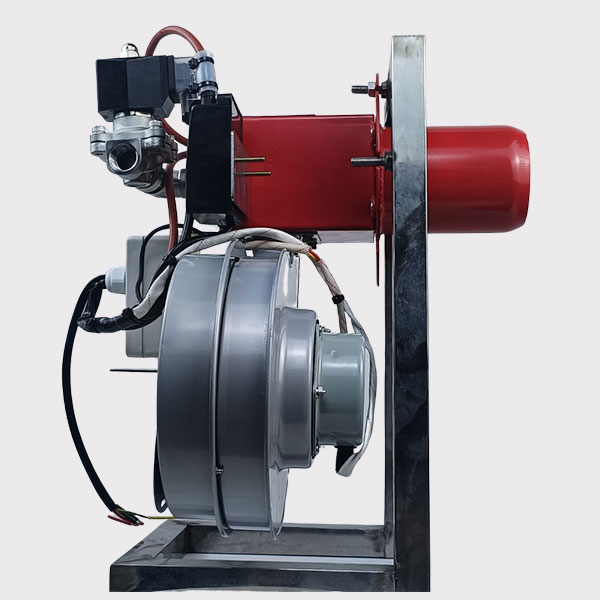

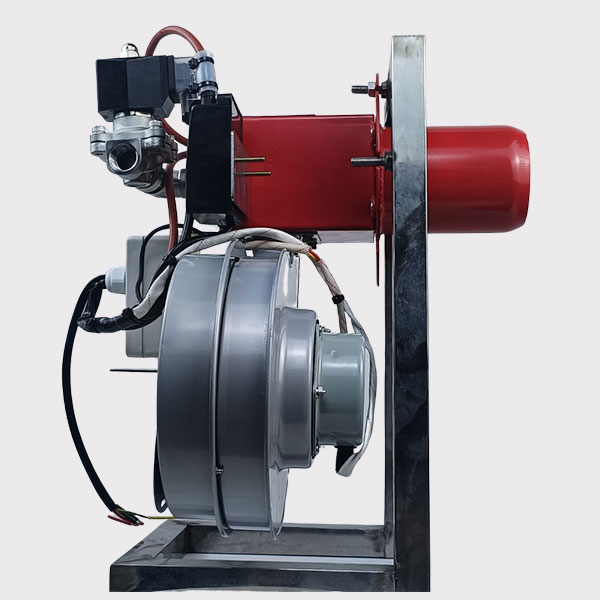

Industrial Gas Burner BNG6 is a small to medium power, industrial-grade single-stage (On/Off control) forced-draft gas burner.

🔘Fuel:gas

🔘Heating Power:30-58kw

🔘Gas Consumption:3-5.8³/h

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Introduction

Question 1-Product Description

GAS BURNER BNG6 SHORT DESCRIPTION

Powerful and Stable Output: Delivers a broad thermal power range from 30 to 58 kW, meeting the rated heating requirements of diverse equipment.

Excellent Fuel Flexibility: One unit, multiple fuel options. Compatible with Natural Gas (NG), Liquefied Petroleum Gas (LP), Propane Air Mix (LA), and specially supports Town Gas (TG) as well as eco-friendly Digester Gas (DG). This offers customers flexible energy choices, making it particularly suitable for waste-to-energy projects.

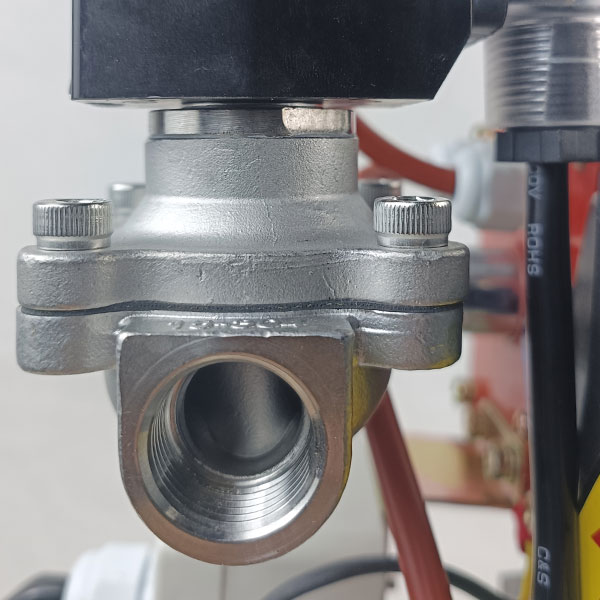

Robust and Reliable Design: Features a forced draft design powered by an efficient motor. Ensures complete combustion and can operate against a combustion chamber back pressure of up to 2.5 mbar, guaranteeing stable operation and strong adaptability.

Simple and User-Friendly Control: Employs single-stage (ON/OFF) control, resulting in a simple system structure, easy commissioning and maintenance, low failure rates, and economical long-term operational costs.

Broad Applicability: Operates on a standard 220V single-phase power supply, facilitating convenient installation and wiring for quick integration into various equipment.

GAS BURNER PRODUCT VIDEO

Question 2-Product Parameter

BNG6 PARAMETERS

| Model | BNG6 |

| Fuel | Natural Gas (NG)| Propane (LP)|Propane Air Mix (LA)|Town Gas (TG) Digester Gas (DG) |

| Power(kw) | 30-58 |

| Gas Flow(m³/h) | 3-5.8 |

| Power Supply | 1N AC 50Hz 220V |

| Motor Power(kw) | / |

| Combustion Chamber Pressure(mbar) | 2.5 |

| Control | One stage fire |

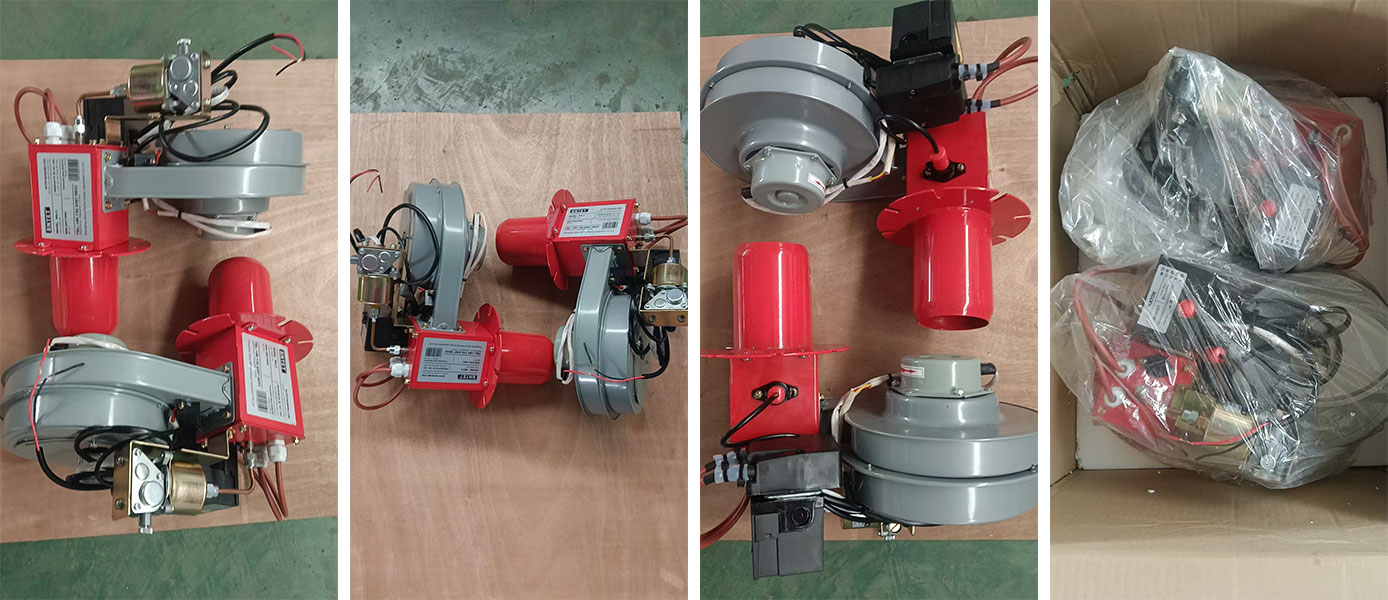

| Packing Size(mm) | 500x440x390 |

| Weight(kg) | 12(Wooden case packing) |

*For more parameters, please contact: info@bntet.com

Question 3-Product Display

BNG6 Industrial Gas Burner

The Industrial Gas Burner BNG6 series is a medium-low power, single-stage industrial gas burner designed for excellence, offering stable performance and robust construction. It combines high efficiency, reliability, and multi-fuel adaptability to deliver a stable and economical flame solution for various commercial and industrial heating equipment. It is the ideal heat source choice for drying, space heating, boilers, and environmental energy projects.

bng6-details01

bng6-details02

Question 4-Application

Hot Air Generators

Used in drying ovens, paint spray booths, grain/agricultural product drying equipment, electroplating tank heating, etc., to supply clean, dry hot air.

Industrial Boilers

Provides heat for small to medium-sized hot water boilers, steam boilers, or thermal oil boilers, used for factory heating, process heating, or domestic hot water supply.

Melting and Holding

Used in melting furnaces and holding furnaces for low-melting-point metals such as aluminum and zinc.

Asphalt Heating and Maintenance

Used for heating and circulation maintenance in asphalt tanks and asphalt mixing plants.

Question 5-FAQ

Q1: Can the BNG6 burner automatically modulate its firepower?

A: No. The BNG6 is a single-stage (ON/OFF) control burner, operating only in two states: "full load operation" and "stop." If you require automatic, continuous modulation of firepower based on temperature or pressure signals, you need to select a burner model equipped with proportional modulation (PID control) functionality.

Q2: Can this burner be used on my [XXX] equipment? (e.g., a 0.5-ton steam boiler, a 100m³ drying chamber)

A: The key factors for selection are power matching and backpressure compatibility. First, your equipment's thermal demand (e.g., boiler evaporation rate) should fall within the burner's 30-58kW output range. Second, the burner must be capable of overcoming the flue gas resistance (backpressure) generated by your equipment's combustion chamber or heating chamber. It is recommended to provide your equipment model or detailed parameters (rated thermal power, combustion chamber dimensions, flue resistance, etc.) for final confirmation by our engineers.

Q3: The burner frequently fails to ignite. What could be the reasons?

A: Please troubleshoot following these steps:

✅Gas side: Check if the gas valve is open, if the pressure is within the normal range, and if the filter is clogged.

✅Air side: Check if the air intake or air damper is blocked, and if the fan rotation direction is correct.

✅Ignition system: Check if the ignition electrodes are correctly positioned (distance, gap), if they are carbon-fouled, and if the high-voltage ignition cable is damaged.

✅Flame monitoring: Check if the ionization electrode (or photocell) is clean, correctly positioned, and securely connected.

✅Control signals: Verify that all safety interlock conditions (e.g., air pressure switch) are satisfied.

Question 6-Our service

Hot Tags: Industrial Gas Burner,Gas Burner,boiler gas burner,BNG6,mini boiler gas burner

You Might Also Like

-

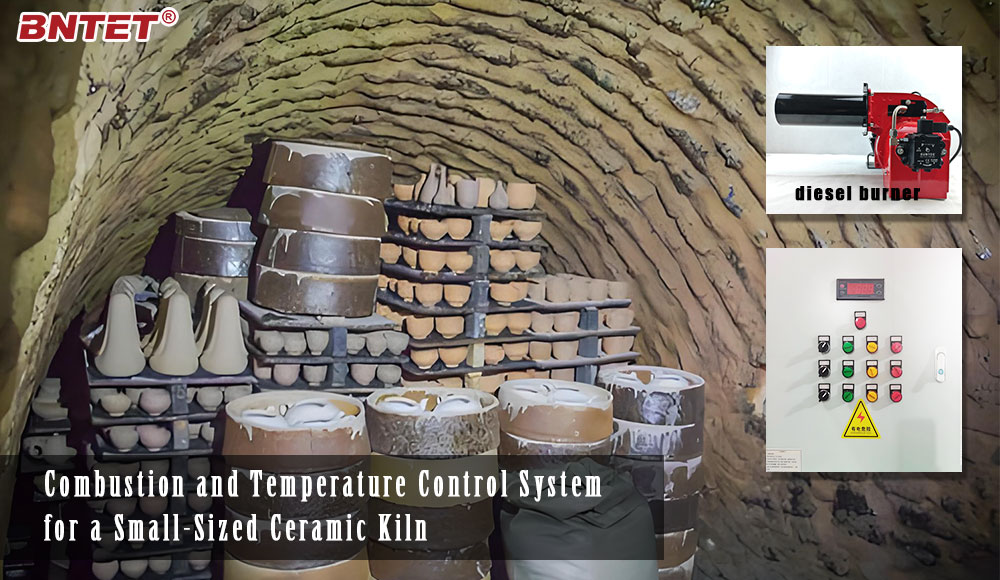

Customized Combustion and Temperature Control System for a Small-S-Sized Ceramic Kiln in Brazil

-

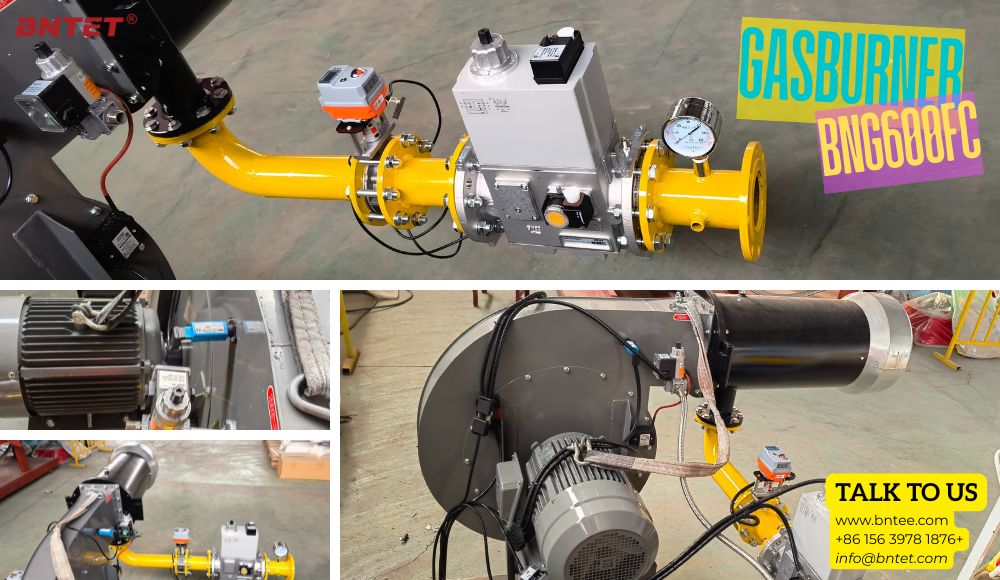

BNG600FC High-Performance Combustion System Exported to the UAE!

-

Turning Rice Husks into Energy: A Case Study of Energy-saving Transformation in a Thai Rice Mill

-

Large Diesel Burners Heading to Spain

-

High-Efficiency Combustion System Helps Food Processors Achieve Energy Savings and Cost Reductions

-

Jordan gas burner with high pressure blower