Rice Husk Burner

Rice husk burners are industrial combustion devices specifically designed for the efficient and clean combustion of rice husks.

🔘Fuel:Rice Husk

🔘Thermal Output:600,000 kcal

🔘Maximum Feed Rate:150KG/H

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Introduction

Question 1-Product Description

Rice Husk Burner Design Principles and Features:

Fuel-Specific Adaptability: Engineered specifically for the physical and chemical properties of rice husks—such as their light weight, high volume, high ash content, and high silica content—ensuring stable feeding, smooth conveyance, and complete combustion.

High-Efficiency Combustion System: Typically employs suspension combustion or fluidized-bed combustion technology. By optimizing the air-fuel ratio (primary and secondary air) and furnace structure, it ensures complete combustion of rice husks at high temperatures, significantly improving combustion efficiency.

Stable Thermal Output: Equipped with automatic feeding and intelligent control systems, it enables stable control of the combustion process and thermal output, meeting the continuous heat demands of industrial production.

Ash Handling: The resulting rice husk ash (rich in silica) can be used as raw material for producing activated carbon, high-quality insulation materials, or soil conditioners, achieving full material circularity.

Question 2-Product Parameter

Specifications and Configuration of 600,000 kcal Rice Husk Burner

| Item (Specifications) | Value (Specifications) | Item (Configuration) | Description (Configuration) |

|---|---|---|---|

| Length | 2.9 (m) | Fire Port | Double-layer; inner layer is perforated heat-resistant steel (10mm thick, 28cm long), erosion-resistant and high-temperature resistant |

| Width | 0.85 (m) | Furnace Chamber | Double-layer: Inner liner (Grade 1 high-aluminum refractory brick + integrally formed high-temperature castable refractory + aluminum silicate insulation cotton); Outer layer (double-layer furnace with circulating air, true air cooling for temperature reduction, 5-layer protection measures) |

| Height | 1.55 (m) | Furnace Top | 30cm-thick prefabricated high-temperature castable refractory component |

| Fire Port Diameter | 230 (mm) | Grate | Biomass cast steel grate |

| Fire Port Height | 70 (cm) | Feeding Method | Auger feeding (floor hopper for easy manual feeding); alternatively, top hopper with material pusher (saves space) |

| Power | 1.5 (KW) | Ignition Method | Diesel automatic ignition system (fast ignition, long service life) |

| Maximum Fuel Consumption | 150KG/H | Controller | Microcomputer-controlled; equipped with temperature/pressure sensor for automatic high/low fire switching and temperature control |

| Weight | 750 (KG) | Base | Channel steel with V-shaped pulleys (easier to move) |

Remarks of 600,000 kcal Rice Husk Burner

For more parameters, models, and related solutions, please contact us.

Question 3-Product Display

Benefits of rice husk burners

Waste-to-Energy: Converts agricultural waste (rice husks) into valuable energy, addressing the environmental issues caused by piling up or discarding husks.

Low-Cost Energy: Very low fuel costs provide a highly economical thermal energy solution for applications such as rice processing, grain drying, industrial steam boilers, and hot water supply.

Carbon-Neutral Cycle: The CO₂ released during combustion originates from photosynthesis during plant growth, resulting in no net increase in atmospheric carbon emissions and aligning with sustainable development principles.

Rice-Husk-Burner-detail1

Rice-Husk-Burner-detail2

Question 4-Application

Rice Milling Industry

Provides process heat for paddy drying and rice milling plants

Industrial Boilers

Replaces gas, oil, or coal to provide steam or thermal energy for industries

District Heating

Used for centralized heating or hot water supply in agricultural parks and grain-producing regions.

Power Generation Systems

Serves as a key component in biomass power plants, converting thermal energy into electricity.

Question 5-FAQ

Q: What is the thermal efficiency of the rice husk burner? How high a temperature can it generate?

A: The combustion efficiency of standard models typically exceeds 85%. The generated flue gas temperature can be adjusted within the range of 700°C to 1050°C, depending on the configuration and application, which is sufficient to meet most industrial drying, steam generation, and heat conversion needs.

Q: Compared to using natural gas or coal, how much can we save by using rice husks as fuel?

A: The extent of savings depends on the local prices of rice husks, natural gas, and coal. However, rice husks, as a processing by-product, typically reduce fuel costs to 30%-50% of coal costs and 10%-20% of natural gas costs. The payback period (considering equipment purchase costs) is generally 1 to 3 years, depending on your thermal energy requirements and operational scale.

Q: What is the level of automation for the rice husk burner? How many operators are required?

A: We offer configurations ranging from basic semi-automatic to fully automatic. Standard fully automatic models are equipped with:

Automatic feeding system

PLC intelligent control system (monitoring temperature, airflow, pressure, etc.)

Safety interlock protection

Under normal and stable operating conditions, only one operator is typically needed for monitoring and daily inspections.

Question 6-Our service

1.Free Preliminary Assessment

Analyze the client’s existing fuel (rice husk) characteristics, thermal requirements (steam/heat/temperature), and site conditions, providing a preliminary technical and economic feasibility report.

2.Customized System Design

Perform integrated design of the combustion system, heat recovery system, and exhaust treatment system based on the client's specific processes (e.g., drying, boiler retrofit, power generation).

3.Commissioning with Live Fuel & Performance Testing

Conduct ignition, temperature ramp-up, and load testing using the client’s actual rice husks. Perform on-site verification of key metrics such as thermal efficiency and emissions to ensure design specifications are met.

4.Spare Parts Supply Program

Provide a list of key wear parts (e.g., refractory bricks, nozzles, sensors) and ensure long-term, stable supply channels.

Hot Tags: Rice Husk Burner,Rice Husk Fired Burner,Rice Hull Burner

You Might Also Like

-

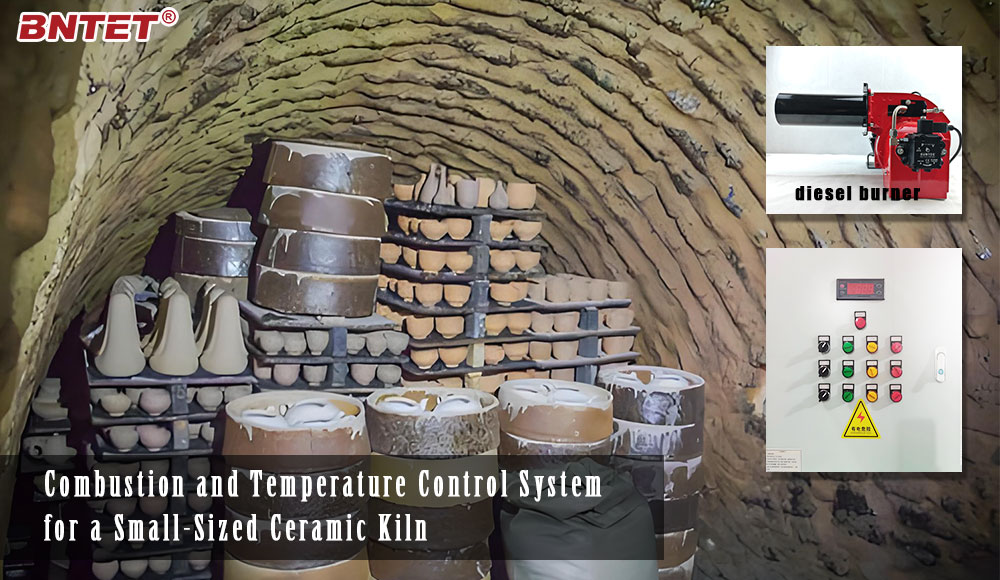

Customized Combustion and Temperature Control System for a Small-S-Sized Ceramic Kiln in Brazil

-

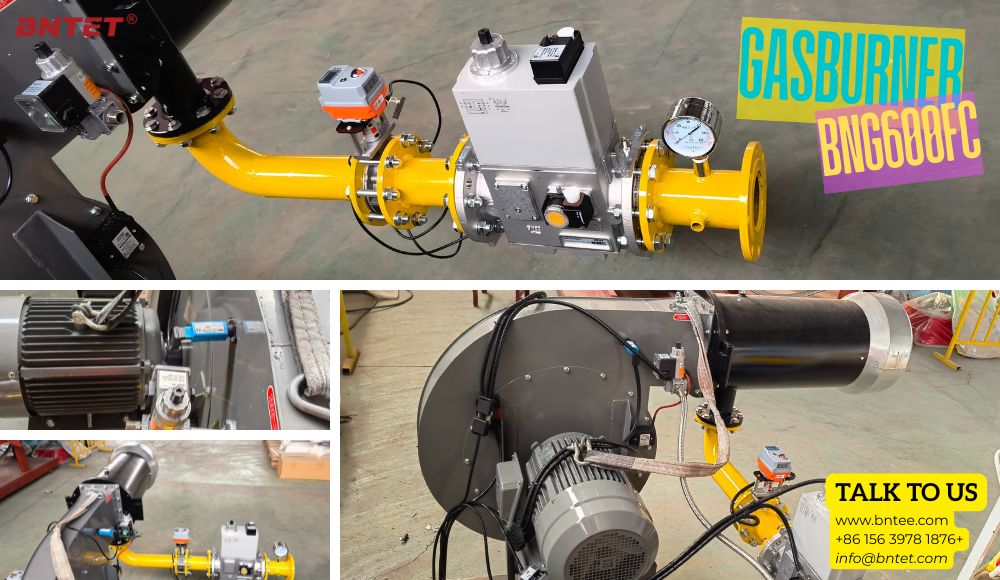

BNG600FC High-Performance Combustion System Exported to the UAE!

-

Turning Rice Husks into Energy: A Case Study of Energy-saving Transformation in a Thai Rice Mill

-

Large Diesel Burners Heading to Spain

-

High-Efficiency Combustion System Helps Food Processors Achieve Energy Savings and Cost Reductions

-

Jordan gas burner with high pressure blower