Industrial Gas Burner BNG400FC

Industrial Gas Burner BNG400FC is a high-power, high-efficiency, multi-fuel compatible industrial-grade burner, mainly used in industrial fields that require stable, controllable, and high-intensity h

🔘Fuel:gas

🔘Heating Power:400-3950kw

🔘Gas Consumption:40.5-399.6³/h

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Introduction

Question 1-Product Description

SHORT DESCRIPTION

♦ Gas burner.

♦ Single-stage operation.

♦ Air-gas mixing at the air duct.

♦ By adjusting the combustion air and the air duct, it is possible to obtain the best combustion values.

♦ The atomizing device can be removed without removing the burner from the boiler, which facilitates maintenance.

♦ Manual air flow regulation.

♦ One flange and one insulating seal for boiler fixing.

♦ Combustion air inlet with air flow regulation.

♦ Sliding boiler coupling flange to adapt to the head protrusion of various types of boilers.

♦ Single-phase electric motor runs the fan.

♦ Flame presence check by ionization electrode.

♦ Electrical equipment protection level IP40.

Question 2-Product Parameter

BNG400FC PARAMETERS

| Model | BNG400FC |

| Fuel | Natural Gas (NG)| Propane (LP)|Propane Air Mix (LA)|Town Gas (TG) Digester Gas (DG) |

| Power(kw) | 400-3950 |

| Gas Flow(m3/h) | 40.5-399.6 |

| Motor Power(kw) | 9 |

| Combustion Chamber Pressure(mbar) | 18.2 |

| Control | Modulating |

| Packing Size(mm) | 1620x1200x1000 |

| Weight(kg) | 320 |

*For more parameters, please contact: info@bntet.com

Question 3-Product Display

Application Advantages Based on Parameter Features:

| Parameter Feature | Application Advantage |

|---|---|

| Multi-Fuel Compatibility (Natural Gas, Propane, Biogas, etc.) | Suitable for diverse energy scenarios, such as biogas recovery projects or areas without natural gas pipelines using LPG. |

| Wide Power Range (400–3950 kW) | Meets demands from small production lines to large industrial systems, offering high flexibility. |

| Modulating Control | Precisely adjusts flame power, adapting to variable load conditions for energy efficiency. |

| High Gas Flow Rate (Up to ~400 m³/h) | Supports continuous operation of high-energy-consumption equipment, such as large kilns. |

| Low Combustion Chamber Pressure Requirement (18.2 mbar) | Low demand on furnace back pressure, compatible with various retrofit projects for existing furnaces. |

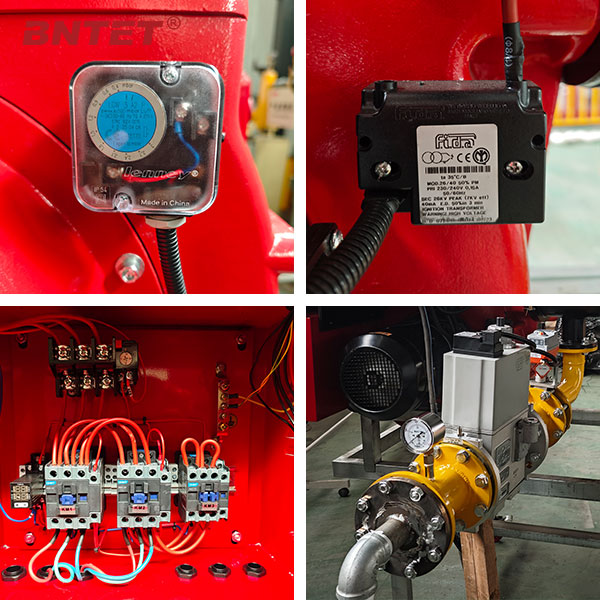

industrial-gas-burner-BNG400FC04-details01

industrial-gas-burner-BNG400FC04-details02

Question 4-Application

Industrial Boiler Systems

Steam Boilers / Hot Water Boilers: Provide process steam or heating hot water for factories, suitable for industries like textiles, chemicals, and food processing.

Heat Treatment and Metal Processing

Melting Furnaces / Holding Furnaces: For melting and holding non-ferrous metals such as aluminum and copper.

Petrochemical and Energy Sectors

Waste Incineration / Biogas Utilization: Compatible with Digester Gas (Biogas), used in environmentally friendly power generation or sludge treatment.

Food and Paper Industries

Drying Equipment: Food drying, paper drying, etc.Sterilization Equipment: High-temperature steam generation.

Question 5-FAQ

Q1: What types of fuel does this burner support? Is it easy to switch between fuels?

A: The BNG400FC is designed as a multi-fuel burner and supports:

Natural Gas (NG)

Propane (LP)

Propane Air Mix (LA)

Town Gas (TG)

Digester Gas / Biogas (DG)

Fuel switching typically requires replacing or adjusting the gas train components, nozzles, and reconfiguring control parameters. It is recommended that this be performed by qualified technicians to ensure safety and optimal performance.

Q2: It has a wide power range (400–3950 kW). How do I select the right power for my equipment?

A: Power selection depends on your specific thermal load requirements. Key factors to calculate include:

The heat demand of your application (e.g., boiler evaporation rate, furnace heating curve).

The calorific value of your fuel.

The overall system thermal efficiency.

We recommend consulting our engineers. Please provide your equipment model, process temperature, and required output for an economical and efficient power recommendation.

Q3: What does "Modulating Control" mean for this burner? What are the benefits?

A: "Modulating Control" means the burner's output can be continuously and infinitely varied between its minimum and maximum firing rates (as opposed to simple on/off or high/low-stage operation).

Key Benefits:

Energy Savings: Precisely matches actual heat demand, avoiding energy waste.

Stable Temperature: Provides smooth thermal output, improving process quality.

Equipment Longevity: Reduces thermal cycling and mechanical wear caused by frequent starts and stops.

Q4: The burner's matching motor power is 9 kW. Is this consumption high?

A: For a thermal device with a maximum output of 3950 kW, a 9 kW combustion air fan motor's power consumption is relatively low and indicates an efficient design. This motor drives the fan, and its consumption is factored into the system's overall efficiency calculation.

Question 6-Our service

Hot Tags: Industrial Gas Burner,Gas Burner,BNG400FC

You Might Also Like

-

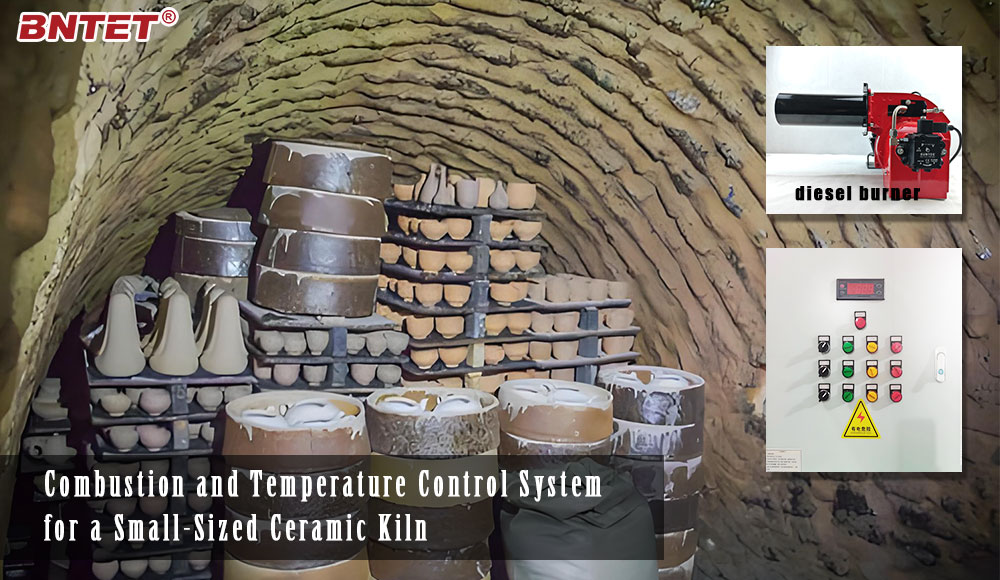

Customized Combustion and Temperature Control System for a Small-S-Sized Ceramic Kiln in Brazil

-

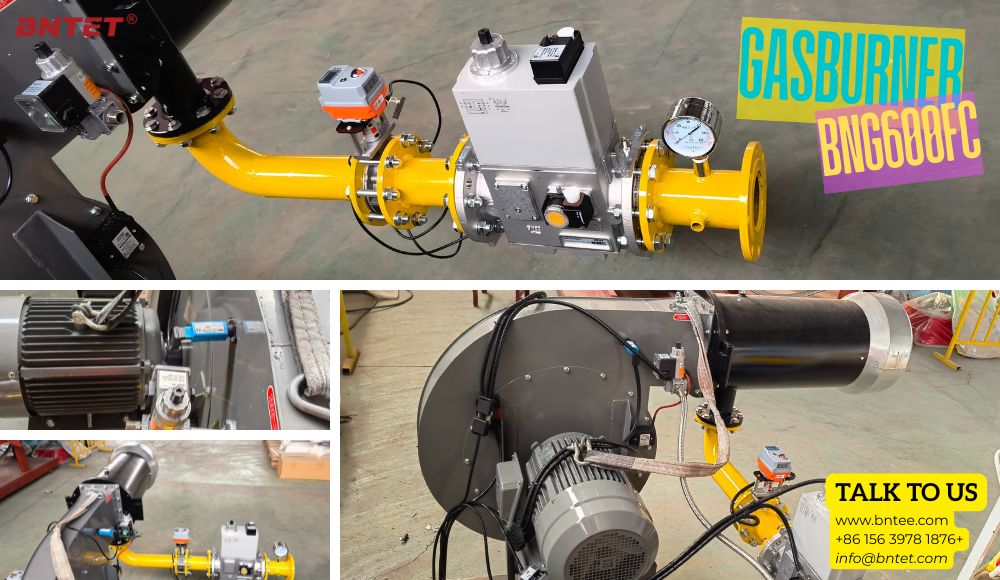

BNG600FC High-Performance Combustion System Exported to the UAE!

-

Turning Rice Husks into Energy: A Case Study of Energy-saving Transformation in a Thai Rice Mill

-

Large Diesel Burners Heading to Spain

-

High-Efficiency Combustion System Helps Food Processors Achieve Energy Savings and Cost Reductions

-

Jordan gas burner with high pressure blower